Pasteurization tunnels

One of the basic conditions for carrying out phase 2 in workmanlike manner is an availability of a tunnel (room) for compost pasteurization. The basic goal of the pasteurization tunnel is creating and supporting necessary temperatures and gaseous air content, uniformly in the whole compost volume that has been filled into the tunnel. The quality of any tunnel, no matter what’s its «origin», is determined by its ability to fulfill its appropriation with less expense on the creation of the tunnel and operating it (filling and unloading the compost, and carrying out pasteurization).

Construction of the pasteurization tunnel

Complete pasteurization tunnel

The «origin» of pasteurization tunnels can be various. They can be «self-made», or their components can be bought overseas. It all depends on your resources added to your wishes and needs. And, as many years’ experience with the work with compost shows, at choosing from what and how to build a pasteurization tunnel, it’s best to follow economic expediency. If you plan on building a little mushroom farm (up to 20 tons of mushrooms a month), then the purchase of the tunnel overseas and the equipment for its operation costs will be compensated after a long period of time. A «weighty» argument in favor of the imported equipment – that it the «human factor» problems, doesn’t represent the truth, to put it mildly. There are more than enough examples for this.

Pasteurization tunnel ready for filling

Pasteurization tunnel with ready phase 2 compost

On one website, dedicated to compost production, it is stated that a pasteurization tunnel will cost you not less than $80,000, and this can be true only if there are big production volumes of phase 2 compost. As for the smaller farms, this number should be and could be much smaller.

The total cost of the tunnel is the cost of the tunnel itself, the ventilation equipment, machinery for filling and unloading the compost and systems for pasteurization maintenance. Knowing the technical tunnel and its equipment requirements, based on the technological parameters of phase 2 compost preparation, depending on the scale of production, it’s usually isn’t hard to choose an optimal option for construction and pasteurization tunnel equipping for the needs of the given farm.

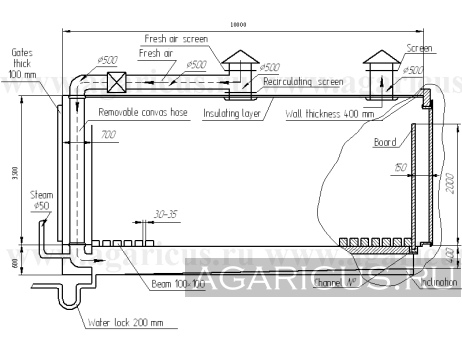

We to your attention a pasteurization tunnel design intended for 20-22 tons of pasteurized (phase 2) compost:

Pasteurization tunnel design

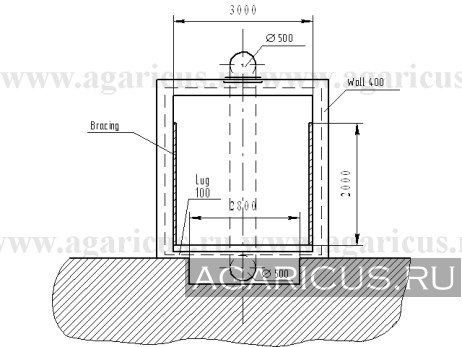

Front view of the pasteurization tunnel

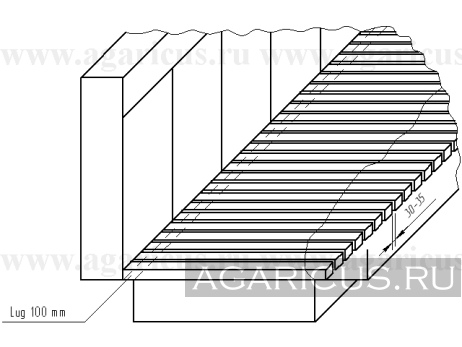

Pasteurization tunnel floor fragment

Construction of the pasteurization tunnel

Complete pasteurization tunnel

The «origin» of pasteurization tunnels can be various. They can be «self-made», or their components can be bought overseas. It all depends on your resources added to your wishes and needs. And, as many years’ experience with the work with compost shows, at choosing from what and how to build a pasteurization tunnel, it’s best to follow economic expediency. If you plan on building a little mushroom farm (up to 20 tons of mushrooms a month), then the purchase of the tunnel overseas and the equipment for its operation costs will be compensated after a long period of time. A «weighty» argument in favor of the imported equipment – that it the «human factor» problems, doesn’t represent the truth, to put it mildly. There are more than enough examples for this.

Pasteurization tunnel ready for filling

Pasteurization tunnel with ready phase 2 compost

On one website, dedicated to compost production, it is stated that a pasteurization tunnel will cost you not less than $80,000, and this can be true only if there are big production volumes of phase 2 compost. As for the smaller farms, this number should be and could be much smaller.

The total cost of the tunnel is the cost of the tunnel itself, the ventilation equipment, machinery for filling and unloading the compost and systems for pasteurization maintenance. Knowing the technical tunnel and its equipment requirements, based on the technological parameters of phase 2 compost preparation, depending on the scale of production, it’s usually isn’t hard to choose an optimal option for construction and pasteurization tunnel equipping for the needs of the given farm.

We to your attention a pasteurization tunnel design intended for 20-22 tons of pasteurized (phase 2) compost:

Pasteurization tunnel design

Front view of the pasteurization tunnel

Pasteurization tunnel floor fragment

Lko:

Saheb hamare mushroom dry bable se pura form doob chuka hai ismein Ham Kya Karen Sahab Koi upay Ho to...

Production of Compost, Personal opinion (part 3). Wet...Abimbola Olaniyi-Balogun, Lagos Nigeria:

Hello there, I made mushroom compost using the long composting method. I used wet chicken manure, fresh...

Mushrooms in KazahstanZagreb, Croatia:

My name is Zlatko Vidmar.

Without chicken manure compost? Yes, it's possible...I am in modern mushroom growing over 40 years.

I see your farm and if...

nanyuki:

my email is samuelnjogo@gmail.com

Without chicken manure compost? Yes, it's possible...nanyuki:

i want to learn like a child on compost making for mushroom

Mushrooms in KazahstanVELLORE TAMILNADU INDIA:

SUITABLE JOBS – MUSHROOMS GROWER / COMPOST / SPAWN OR RELAVANT FIELDS

Without chicken manure compost? Yes, it's possible...Dear Hiring Manager...

Patna:

PLEASE SEND YOUR FORMULA without-chicken-manure-compost

watering first flush mushroomswasil, Malaysia:

i suggest you not to water on mush just maintain the good humidity if you not have any auto system for...

Compost Production. Personal opinion (Part 2)NARENDER SEHRAWAT, FARIDABAD NCR:

COMMON PROBLEM IN PHASE 1 BUNKAR IS THE UNBALANCED TEMERATURE, IT STARTS FROM 50-55 DEGREES TO 78-82...

Without chicken manure compost? Yes, it's possible...Hannes, Plettenberg Bay, South Africa:

Can you give me more details on compost without chicken manure for mushroom growing, what alternatives...