The Urals – compost and mushrooms

31 èþëÿ 2013

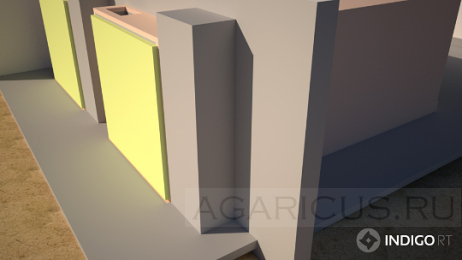

The future mushroom complex

In order to solve this problem, two main case scenarios were considered.The first one is to use tried-and-true methods. In other words, to turn to a foreign company, to pay a “stratospheric” price, and to believe that the attracted foreign specialists would create mushroom production in Russia, which could compete with European mushroom producers (truly, there are no limits to naivety!) False convenience of this approach gets cancelled completely by its cost (especially in case of large production volumes). But the main thing is that following the example of the Dutchmen, we only see their backs. This fact is confirmed by the numerous examples when projects based on technologies of the past ages were offered at large prices.

The second scenario is to gather a team of “brains”, capable of expanding the information on mushroom production given by specialists into a unique project, which allows not only to keep up with the Western advanced mushroom-producers, but also to seize the initiative in determining the future Russian mushroom production. This will help not to be dependent on Holland, Poland and other countries, on their true commercial interests, mood changes, etc., which are conditioned to the perception of our country at the level of African countries (we speak on mushroom production).

The most important moment of such an approach is choosing a specialist who can give all necessary information on compost production, mushroom cultivation, and creation of these production operations. A specialist who has knowledge based on longstanding experience of practical work on mushroom production under different conditions. A person who can serve as a mastermind and a thought leader of the team implementing the project.

The management of the mentioned above organization decided to choose the second way after having analyzed the results of our communication.

To create mushroom production, an available room – a former workshop with an adjoining warehouse – was given. The size is 42x72 meters. The result of the team work is the project which enables to fit compost production and mushroom cultivation for 600 tons a year on such a small area.

During the work on the project, the drafting three-dimensional modeling technology with exporting results to AutoCAD and other systems of computer-assisted design was mastered. This gave an opportunity to dramatically reduce terms of design and issue of implementation drawings.

Generally, the whole project became possible due to application of a whole complex of technological novelties developed by me during last years.

For example, for the first time the 1st composting phase will be completely controlled according to temperature modes and oxygen concentration, and this minimizes dry matter loss and radically reduces terms of composting. In this respect, the design of bins contributes to high homogeneity of compost. These technological nuances will maintain stable quality of compost at any time of a year at the same term of the 1st phase less than 2 weeks, including straw soaking. To add to this, the design of bins allows using fans, where operating pressure is several times lower than the recommended one for bins of the 1st phase. And at some temperatures of compost, it is possible to operate with natural draft. In other words, without fans.

During the second phase several novelties are planned to be introduced – using warmth, produced by compost for delivery air heating during winter time, possibility of controlling ready-made compost humidity, controlling fan pressure and efficiency.

Speaking simply, for readers, not versed in mushroom production, it is quite possible that this technology will be applied for the first time ever.

In the mushroom cultivation area there are also a lot of interesting technological solutions on climate in growing rooms.

Currently construction works started in the building of the future complex.

Dear visitors, it is quite possible that many of you will remember the saying “Count your chickens before they are hatched” while reading this article. I would say that we do and will do the best to have something to count, and there are reasons to be sure that hopes we stake on this complex will become a reality.

Growing rooms will be here

The composting area will be here

Pouring floors for growing rooms

Ready-made floor

Preparation of concrete pouring for a circulating water container

Construction of the first-phase bunkers

A model of pasteurization tunnels

A model of pasteurization tunnels

Three-dimensional drafting modeling speeds up the process of complex designingLko:

Saheb hamare mushroom dry bable se pura form doob chuka hai ismein Ham Kya Karen Sahab Koi upay Ho to...

Production of Compost, Personal opinion (part 3). Wet...Abimbola Olaniyi-Balogun, Lagos Nigeria:

Hello there, I made mushroom compost using the long composting method. I used wet chicken manure, fresh...

Mushrooms in KazahstanZagreb, Croatia:

My name is Zlatko Vidmar.

I am in modern mushroom growing over 40 years.

I see your farm and if...

nanyuki:

my email is samuelnjogo@gmail.com

Without chicken manure compost? Yes, it's possible...nanyuki:

i want to learn like a child on compost making for mushroom

Mushrooms in KazahstanVELLORE TAMILNADU INDIA:

SUITABLE JOBS – MUSHROOMS GROWER / COMPOST / SPAWN OR RELAVANT FIELDS

Dear Hiring Manager...

Patna:

PLEASE SEND YOUR FORMULA without-chicken-manure-compost

watering first flush mushroomswasil, Malaysia:

i suggest you not to water on mush just maintain the good humidity if you not have any auto system for...

Compost Production. Personal opinion (Part 2)NARENDER SEHRAWAT, FARIDABAD NCR:

COMMON PROBLEM IN PHASE 1 BUNKAR IS THE UNBALANCED TEMERATURE, IT STARTS FROM 50-55 DEGREES TO 78-82...

Without chicken manure compost? Yes, it's possible...Hannes, Plettenberg Bay, South Africa:

Can you give me more details on compost without chicken manure for mushroom growing, what alternatives...

Comments

Nicoleta Matei, Focsani, Romania, 13 àâãóñòà 2019:

Dear investor,

You have a great opportunity to invest in Romania now.

The potential to get high profit is huge.

Here are the reasons:

1) We produce food for people - Pleurotus mushrooms.

2) We have no competition - this is the only business in Romania of such type.

3) We have the available market - in Romania, in the ex-communist countries

4) We have the necessary raw materials.

For the beginning:

1) We have the compost factory in good functioning, with the employees we need.

The factory can be rented for an acceptable sum of money.

The rent will be paid out of the income the factory produces.

2) In order for the factory to function for the investor's profit, we need a 50.000 euros working capital.

3) We will apply to build a project of 40 mushrooms growing tunnels.

The value of this project may be 2.000.000 euros:

- 1.800.000 euros E.U. grant

- 200.000 euros our own contribution

- 250.000 euros collateral expenses for the implementation of the project

4) You buy the compost factory.

The highest purchase value is 1.500.000 euros.

Conclusion:

* The investor will finally invest 2.000.000 euros and he / she will purchase:

- a compost factory for Pleurotus mushrooms growing with a production capacity of 12.000 tons/year.

- a Pleurotus mushrooms growing farm with a production capacity of 800 tons / year.

Income:

- 6.000 tons of compost for sales x 135 euros / ton = 810.000 euros / year

- 800 tons of bulk mushrooms x 1.200 euros = 960.000 euros / year.

- total income: 1.770.000 euros / year

- profits 25% = 442.500 euros / year

- investment amortization - 5 years

Note * The mushrooms processing can double the income.

e-mail address for contacts: crinalbastru82@yahoo.com

phone number for contacts: 0040/0720884150